3 minutes, 4 seconds

-25 Views 0 Comments 0 Likes 0 Reviews

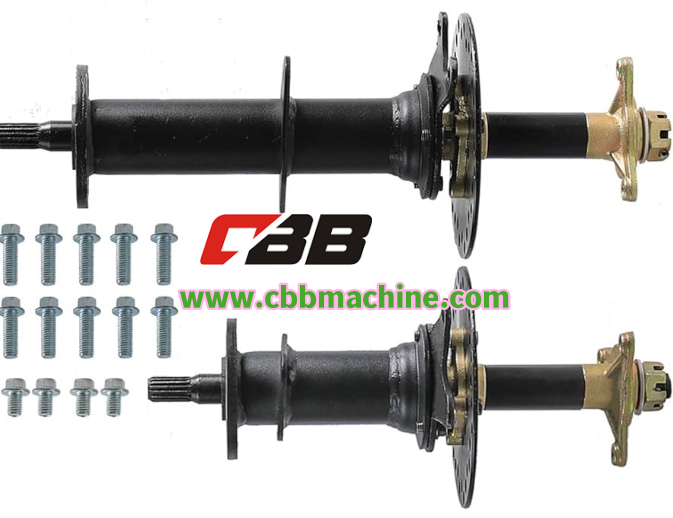

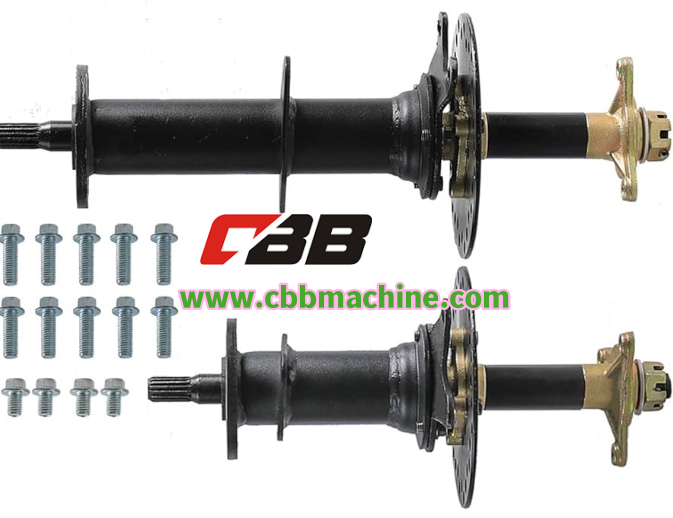

Achieving consistent tension during high-speed slitting, rewinding, and web processing operations is a fundamental requirement in modern production lines. The Differential Shaft developed by Cbbmachine provides an intelligent and dependable solution for manufacturers managing multiple web widths or uneven tension loads across substrates. Its advanced design ensures precise slip torque control and individual reel adjustment, even under dynamic operating conditions.

Unlike conventional shafts that rotate uniformly, this shaft allows each core to rotate independently, automatically compensating for thickness or tension variations during winding. This feature is especially critical for maintaining alignment and preventing material deformation, which can lead to product defects or increased scrap. The shaft’s ability to regulate torque distribution in real time makes it a must-have component in industries like flexible packaging, adhesive labels, film converting, and paper processing.

The core mechanism of the shaft incorporates multiple frictional elements—such as ball-type, air pressure, or spring-tension systems—that allow for finely tuned torque settings across individual cores. As a result, the shaft enables uniform winding regardless of material thickness differences or speed fluctuations. The user can adjust the tension with minimal effort, helping operators maintain control while increasing productivity.

Durability and compatibility are also strong points of this shaft. Constructed from high-strength alloys and precision-balanced components, it can withstand continuous operation in demanding environments without compromising performance. Available in various lengths, diameters, and slip-control mechanisms, it integrates easily into existing machines or custom setups.

In addition, the maintenance process is streamlined thanks to its modular structure. Friction rings or sleeves can be replaced quickly, minimizing downtime and keeping operations running smoothly. This translates to fewer production delays and a longer service life—an advantage for businesses focused on reliability and return on investment.

Whether you're processing multiple web rolls or facing variable material characteristics, this shaft provides the control needed to meet demanding specifications without slowing your workflow. It’s a proven upgrade for manufacturers aiming to minimize waste, improve roll quality, and operate with greater flexibility.

To see how this precision shaft can optimize your production line, visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html and explore a smarter approach to web handling—where every core counts.